汽车离合器分离轴承试验台总体设计

汽车离合器分离轴承试验台总体设计[摘要]随着汽车行业的不断发展,越来越多的汽车走入寻常百姓家中,人们也越来越关注汽车的性能与行驶寿命,汽车行业也因此推动了技术的发展。汽车离合器分离轴承及其单元是汽车的重要组成部分,其主要是经过轴承的轴向方向的移动来实现汽车的发动机与传动系统的结合与切断,在汽车动力的传输有着重要作用。使得汽车在起步,加减档,停车以及平稳的安全行驶扮演者重要的角色。这次的毕业设计主要是通过模拟汽车离合器分离轴承试验来进行精准得知离合器轴承的损耗与失效的原因与其影响。[关键词]汽车离合器分离轴承OverallDesignofAutomobileClutchSeparationBea...

相关推荐

-

互联网产品的品牌广告传播——以小米手机为例

2022-10-16 62

2022-10-16 62 -

郑州方特旅游电子商务营销策略研究

2022-10-17 84

2022-10-17 84 -

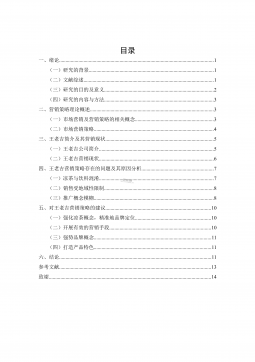

王老吉的市场营销策略研究

2022-10-17 74

2022-10-17 74 -

电影《中国机长》在抖音短视频平台的营销策略分析

2022-10-17 57

2022-10-17 57 -

滨河酒营销策略分析

2022-10-17 81

2022-10-17 81 -

传统商业企业与电子商务企业的异同及其挑战应对

2024-02-26 44

2024-02-26 44 -

基于PEST的我国农业电子商务竞争分析

2024-02-28 29

2024-02-28 29 -

关于新零售的论文(优秀范文6篇)

2024-02-28 30

2024-02-28 30 -

电子商务中农产品配送存在的问题与优化措施

2024-02-28 49

2024-02-28 49 -

敦煌网跨境电商经营模式与运营策略

2024-02-28 77

2024-02-28 77

相关内容

-

基于绿色农业的电子商务发展模式研究

分类:社科文学类资料

时间:2024-02-29

标签:无

格式:DOCX

价格:免费

-

家乐园速购同城购物网站电子商务运营方案研究

分类:社科文学类资料

时间:2024-02-29

标签:无

格式:DOCX

价格:免费

-

江苏农业电子商务发展问题与优化措施

分类:社科文学类资料

时间:2024-02-29

标签:无

格式:DOCX

价格:免费

-

江阴学院学生“花之韵花茶铺”网店创业运营探析

分类:社科文学类资料

时间:2024-02-29

标签:无

格式:DOCX

价格:免费

-

经济新常态下的跨境电子商务经营模式探讨

分类:社科文学类资料

时间:2024-02-29

标签:无

格式:DOCX

价格:免费