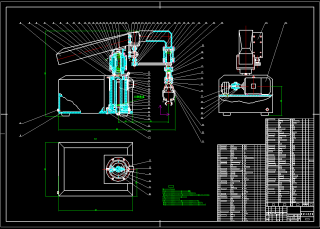

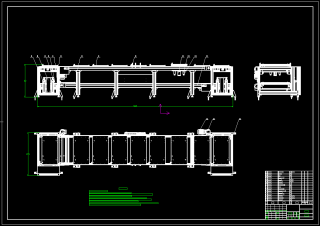

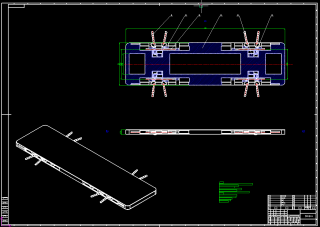

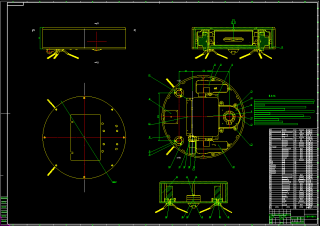

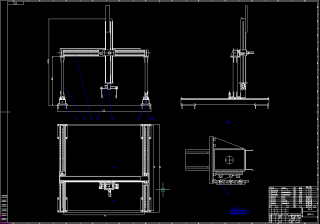

带式传送机构及机械手PLC控制设计

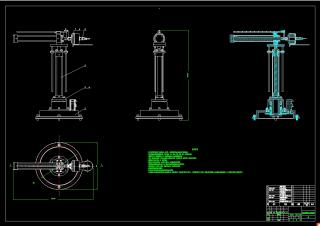

摘要生产线通常由传送带组成。生产中或加工后的产品运至生产线进行包装加工。自动生产线中使用的输送装置的目的是将所有配备的包装工艺设备有机地连接在一起,形成一个整体。起到中间传递的作用,还完成了包装物和包装材料的输入和包装,输送装置的工作性能也会影响自动化程度、生产能力、包装质量、产品成本、运行条件以及整个生产线的卫生安全。必须根据工艺要求和总体布局进行合理设计和选择。机械手是典型的机电产品,机械手的研究需要机械、电子、信息学和计算机知识的结合。复合移动机器人主要使用的是小型、轻载的协作型机械臂,兼具高效率、连续性、精确性、灵活性和安全性,可以与人在车间协同作业,成为集物料缓存、搬运、上下料等功能...

相关推荐

-

肘关节康复机器人说明书

2022-11-23 198

2022-11-23 198 -

六自由度机械臂设计说明书

2022-11-25 201

2022-11-25 201 -

旋盖机械手设计(机械毕业设计+说明书+全套CAD)

2022-12-11 144

2022-12-11 144 -

冲压专用机械手设计(机械毕业设计+说明书+全套CAD)

2022-12-18 84

2022-12-18 84 -

涂漆机器人工作站上料机构设计(机械毕业设计+说明书+全套CAD)

2023-01-02 91

2023-01-02 91 -

智能停车机器人的设计与仿真(机械毕业设计+说明书+全套CAD)

2023-01-05 219

2023-01-05 219 -

家用智能清扫机器人设计(机械毕业设计+说明书+全套CAD)

2023-01-19 309

2023-01-19 309 -

四轴搬运机器人(机械毕业设计+说明书+全套CAD)

2023-01-27 681

2023-01-27 681 -

邮递包裹用并联分拣机械手设计(机械毕业设计+说明书+全套CAD)

2023-02-01 164

2023-02-01 164 -

高枝摘苹果加长机械手的设计-机械毕业设计资料原创设计

2023-11-23 84

2023-11-23 84

相关内容

-

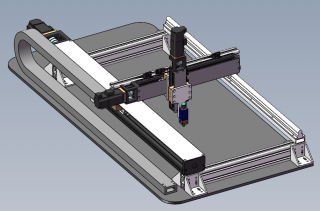

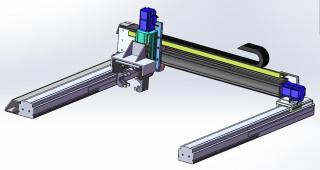

基于三维直线模组的自动注射设备结构设计-机械结构设计-原厂毕设资料

分类:非标机械电气自动化

时间:2024-01-21

标签:结构设计

格式:ZIP

价格:200 光币

-

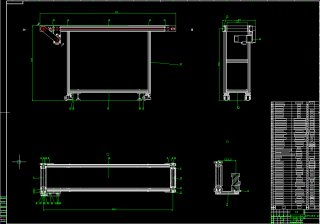

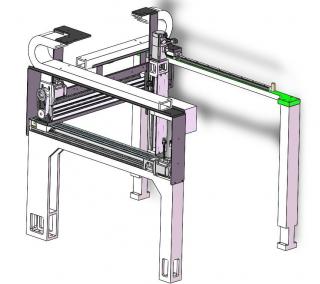

基于三维直线模组的物料搬运设备结构设计-机械毕业设计资料原创

分类:非标机械电气自动化

时间:2024-01-21

标签:结构设计

格式:ZIP

价格:200 光币

-

基于三维直线模组的贴标设备结构设计-机械毕业设计资料论文资料

分类:非标机械电气自动化

时间:2024-01-21

标签:结构设计

格式:ZIP

价格:200 光币

-

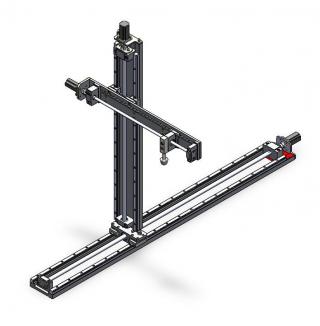

简易三自由度搬运机械手结构设计-原创设计资料-机械毕业设计资料

分类:非标机械电气自动化

时间:2024-01-29

标签:结构设计

格式:ZIP

价格:150 光币

-

轮履式变结构全方位移动机器人运动学分析与结构-原创机械毕业设计资料-三维-CAD-运动仿真视频-创意机械毕业设计

分类:非标机械电气自动化

时间:2024-02-16

标签:结构

格式:ZIP

价格:200 光币