红枣去核机的机构设计

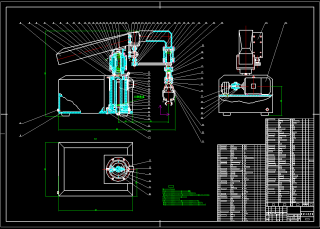

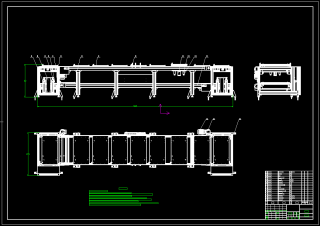

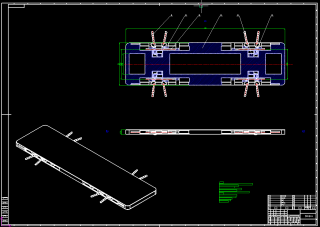

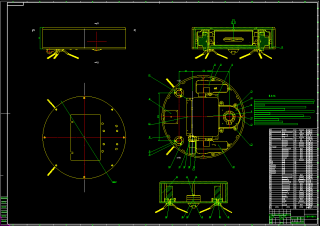

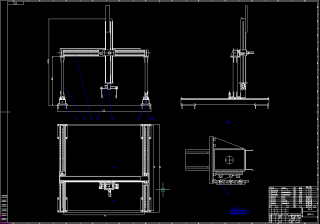

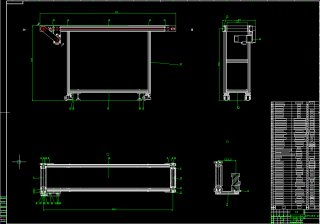

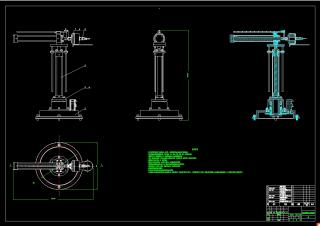

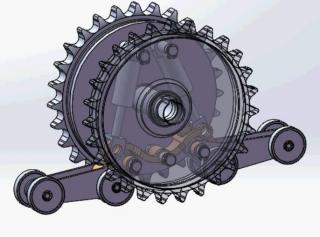

摘要红枣是大多数人尤其女性爱吃的食物,其对人体身体健康具有明显作用,而现代对红枣的加工引用了自动化技术,出现许多红枣去核切片机器,但其切制的红枣片厚度不均,枣肉破碎率高,枣核残留等问题,同时需要人员辅助运行,劳动强度高,自动化程度低,故急需更加智能、可靠的新型红枣去核切片机,红枣切片机可大大减轻劳动强度,生产效率高,使用省力,符合食品加工机械卫生标准要求。切割后成品表面光滑、不破坏组织。匀称,切割速度快,减少劳动成本。本文通过机械结构的角度设计了红枣切片机集成,拥有红枣自动定向排序、夹紧去核、枣肉切片等功能,由辊筒输送链供料、采用槽轮结构间歇夹紧,采用两排平行放置的链实现定位和夹紧;去核装置采...

相关推荐

-

肘关节康复机器人说明书

2022-11-23 196

2022-11-23 196 -

六自由度机械臂设计说明书

2022-11-25 200

2022-11-25 200 -

旋盖机械手设计(机械毕业设计+说明书+全套CAD)

2022-12-11 144

2022-12-11 144 -

冲压专用机械手设计(机械毕业设计+说明书+全套CAD)

2022-12-18 84

2022-12-18 84 -

涂漆机器人工作站上料机构设计(机械毕业设计+说明书+全套CAD)

2023-01-02 91

2023-01-02 91 -

智能停车机器人的设计与仿真(机械毕业设计+说明书+全套CAD)

2023-01-05 219

2023-01-05 219 -

家用智能清扫机器人设计(机械毕业设计+说明书+全套CAD)

2023-01-19 309

2023-01-19 309 -

四轴搬运机器人(机械毕业设计+说明书+全套CAD)

2023-01-27 680

2023-01-27 680 -

邮递包裹用并联分拣机械手设计(机械毕业设计+说明书+全套CAD)

2023-02-01 164

2023-02-01 164 -

高枝摘苹果加长机械手的设计-机械毕业设计资料原创设计

2023-11-23 84

2023-11-23 84

相关内容

-

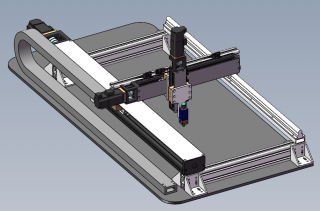

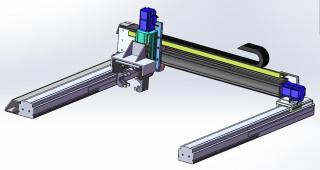

基于三维直线模组的自动注射设备结构设计-机械结构设计-原厂毕设资料

分类:非标机械电气自动化

时间:2024-01-21

标签:结构设计

格式:ZIP

价格:200 光币

-

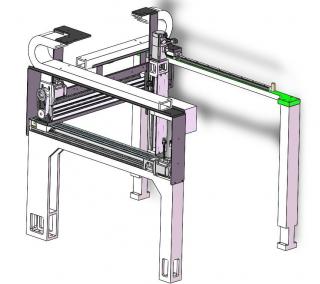

基于三维直线模组的物料搬运设备结构设计-机械毕业设计资料原创

分类:非标机械电气自动化

时间:2024-01-21

标签:结构设计

格式:ZIP

价格:200 光币

-

基于三维直线模组的贴标设备结构设计-机械毕业设计资料论文资料

分类:非标机械电气自动化

时间:2024-01-21

标签:结构设计

格式:ZIP

价格:200 光币

-

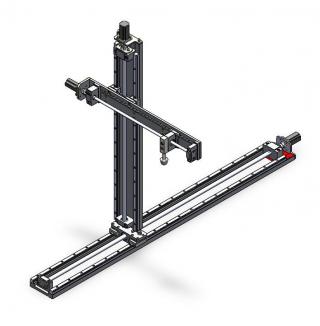

简易三自由度搬运机械手结构设计-原创设计资料-机械毕业设计资料

分类:非标机械电气自动化

时间:2024-01-29

标签:结构设计

格式:ZIP

价格:150 光币

-

轮履式变结构全方位移动机器人运动学分析与结构-原创机械毕业设计资料-三维-CAD-运动仿真视频-创意机械毕业设计

分类:非标机械电气自动化

时间:2024-02-16

标签:结构

格式:ZIP

价格:200 光币