自移式液压支架外文文献翻译、中英文翻译

翻译部分英文原文(见参考文献[19].P157)SELF-ADVANCINGHYDRAULICPOWEREDSUPPORTSModernlongwallminingemployshydraulicpoweredsupportsatthefacearea.Thesupportnotonlyholdsuptheroof,pushesthefacechainconveyor,andadvancesitself,butalsoprovidesasafeenvironmentforallassociatedminingactivities.Thereforeitssuccessfulselectiona...

相关推荐

-

碧桂园滨江府模板专项施工方案

2022-11-24 183

2022-11-24 183 -

大型综合体地下室混凝土浇筑控制技术与重点--x

2023-04-30 83

2023-04-30 83 -

JA建筑公司成本控制的问题与对策--x

2023-04-30 118

2023-04-30 118 -

藏艺文博园规划设计中藏文化的保护传承--x

2023-04-30 124

2023-04-30 124 -

不同类型加固工程与加固方案分析--x

2023-04-30 130

2023-04-30 130 -

ZigBee技术下楼宇火灾自动报警平台的开发研究--x

2023-04-30 122

2023-04-30 122 -

不同类型的房地产开发项目的类型与开发特点--x

2023-04-30 364

2023-04-30 364 -

大连湾海底隧道工程的安全管理新思路和方法--x

2023-04-30 246

2023-04-30 246 -

电梯等待时间最短的数学模型研究--x

2023-04-30 207

2023-04-30 207 -

港珠澳大桥论文(参考研究范文6篇)--x

2023-04-30 999+

2023-04-30 999+

相关内容

-

高层建筑电气设计

分类:土木建筑化工水利

时间:2023-09-20

标签:设计

格式:ZIP

价格:30 光币

-

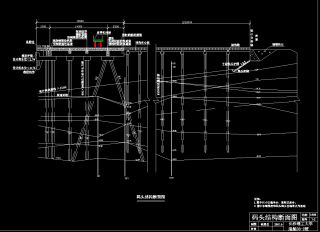

港件杂货港区总平面布置与码头结构设计

分类:土木建筑化工水利

时间:2023-10-07

标签:结构设计

格式:ZIP

价格:50 光币

-

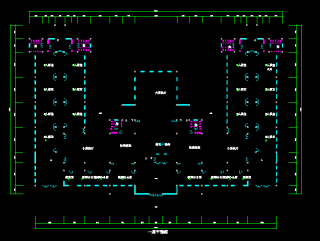

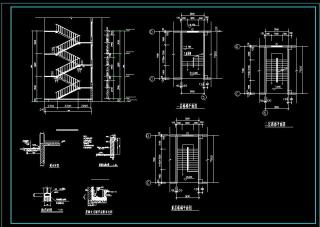

房屋建筑学-楼梯平面图-建筑大样图

分类:土木建筑化工水利

时间:2023-10-10

标签:无

格式:ZIP

价格:10 光币

-

基于6层建筑用电负荷等级(论文+DWG图纸+外文翻译+文献综述+开题报告)

分类:土木建筑化工水利

时间:2023-10-24

标签:开题报告

格式:ZIP

价格:30 光币

-

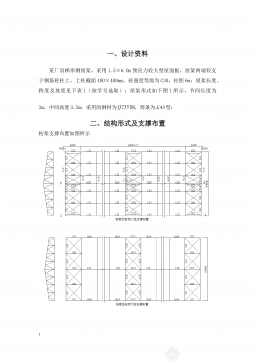

某厂房梯形钢屋架,采用1.5×6.0m预应力砼大型屋面板

分类:土木建筑化工水利

时间:2024-07-01

标签:无

格式:DOC

价格:30 光币