水平定向钻机孔底钻具的研究与应用--中英文翻译

HorizontalDirectionalDrillHoleDrillendofthestudyandapplicationofadrillholeendofacompositionandfunction.Constructionofdrillholeorientation:drillpipe,alaunchertubeandaguidetoaccommodatebit.Constructionofdrillholeorientationwithdrilling,tochange,throughmagneticanddrillingfluiddeliveryfunctions.Coordina...

相关推荐

-

论文提纲农业硕士论文写作中的常见问题及对策

2023-07-07 37

2023-07-07 37 -

3854字论文写作指导商务英语论文大纲

2023-07-07 45

2023-07-07 45 -

论文范文个人信用评价体系建设的现状及策略

2023-07-07 33

2023-07-07 33 -

1141字论文写作指导毕业论文大纲

2023-07-07 39

2023-07-07 39 -

3247字论文写作指导税务文书概要

2023-07-07 20

2023-07-07 20 -

36142字硕士毕业论文杨希闵生活、朋友与文学作品研究

2023-07-07 27

2023-07-07 27 -

34222字硕士毕业论文史传传统下的贾平凹小说研究——以强秦、鲁谷、戴登、老生为中心

2023-07-07 36

2023-07-07 36 -

29542字硕士毕业论文韩少功的小说创作与湘西民间文学文化

2023-07-10 41

2023-07-10 41 -

农业机械化概念界定与理论基础,农业机械狭义定义简介

2023-07-19 31

2023-07-19 31 -

开题报告在线电磁钢轨探伤数据处理及信息管理方法研究

2023-08-30 46

2023-08-30 46

相关内容

-

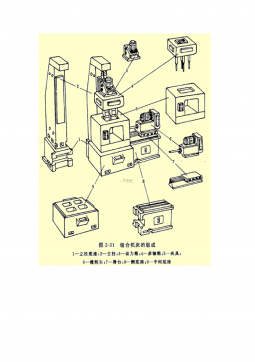

GB 3668.9-1983 组合机床通用部件 主轴部件尺寸

分类:课程设计课件资料

时间:2023-10-03

标签:无

格式:PDF

价格:5 光币

-

GB 3668.10-1983 组合机床通用部件 多轴箱主轴端部和可调接杆尺寸

分类:课程设计课件资料

时间:2023-10-03

标签:无

格式:PDF

价格:5 光币

-

W组合机床设计简明手册

分类:课程设计课件资料

时间:2023-10-03

标签:设计

格式:PDF

价格:5 光币

-

组合机床设计参考图册

分类:课程设计课件资料

时间:2023-10-03

标签:设计

格式:PDF

价格:5 光币

-

组合机床实例

分类:课程设计课件资料

时间:2023-10-03

标签:无

格式:DOC

价格:5 光币