一些离合器的简介外文文献翻译、中英文翻译

附录ALittleBriefIntroductionOfClutchNowadaysthepioneersoftheclutchdisc,clutchdiscismorepiecesofituntil1925later.Themulti-gearclutchmainadvantageisthatcarstartedtheclutchengagementisnoimpactonthesmooth.Earlyinthedesign,layoutdesign,accordingtoslicepairsofasteelplatewithabronzeblanks.Usingthefrictionpai...

相关推荐

-

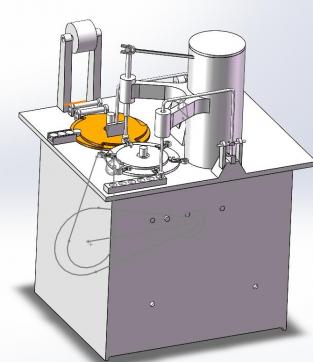

立式打蛋机设计(全套CAD图纸+说明书+三维设计)

2022-10-19 375

2022-10-19 375 -

全自动打捆机(机械毕业设计+说明书+全套CAD)

2022-11-06 180

2022-11-06 180 -

输出轴的数控工艺及主要工装设计(机械毕业设计+说明书+全套CAD)

2022-11-07 402

2022-11-07 402 -

爬楼梯智能轮椅设计(机械毕业设计+说明书+全套CAD)

2022-11-20 172

2022-11-20 172 -

枕式包装机设计(机械毕业设计+说明书+全套CAD)

2022-11-25 628

2022-11-25 628 -

自动盖章机(机械毕业设计+说明书+CAD)

2022-12-15 916

2022-12-15 916 -

挂轮架加工工艺与工装设计(机械毕业设计+说明书+全套CAD)

2023-01-16 446

2023-01-16 446 -

柴油机P型喷油器设计-机械毕业设计资料

2023-08-28 128

2023-08-28 128 -

下肢康复机器人踝关节驱动系统-设计

2023-10-07 128

2023-10-07 128 -

粒状巧克力糖包装机设计-包含SW设计-机械毕业设计资料-机械毕业设计

2024-09-30 110

2024-09-30 110

相关内容

-

基于三维建模的液体平面点胶装置结构设计-全套CAD

分类:非标机械电气自动化

时间:2024-12-10

标签:结构设计

格式:ZIP

价格:200 光币

-

机匣翻转清洗机机械及电控系统设计-CAD

分类:非标机械电气自动化

时间:2024-12-10

标签:设计

格式:ZIP

价格:200 光币

-

含非线性能量阱的转子系统结构设计-全套CAD图纸

分类:非标机械电气自动化

时间:2024-12-10

标签:结构设计

格式:ZIP

价格:200 光币

-

海上风机实验加载机构设计

分类:非标机械电气自动化

时间:2024-12-10

标签:设计

格式:ZIP

价格:150 光币

-

公路下水井疏通装置机电系统设计-包含CAD全套

分类:非标机械电气自动化

时间:2024-12-10

标签:设计

格式:ZIP

价格:200 光币