变压器滤油机的研究(中英文4899字)

附录C外文文献及翻译(变压器滤油机)StudyofTransformerOilFiltrationMachineShreyaSalvi1,A.P.Paranjape2,1M.E.student,Dept.ofElectricalPowerSystem,P.E.S.CollegeofEngineering,Aurangabad,Maharashtra,India2Professor,Dept.ofElectricalPowerSystem,P.E.S.CollegeofEngineering,Aurangabad,Maharashtra,India------------------------...

相关推荐

-

基于PLC控制的机械手设计(CAD)

2022-10-25 174

2022-10-25 174 -

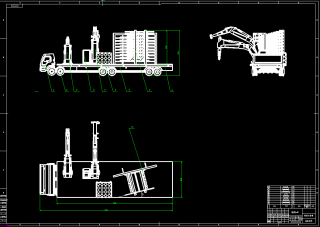

全自动植树机设计结构设计(机械毕业设计+说明书+全套CAD)

2022-11-22 272

2022-11-22 272 -

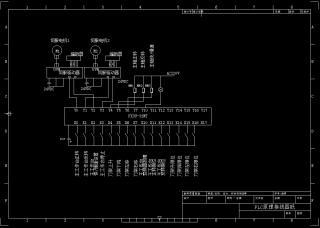

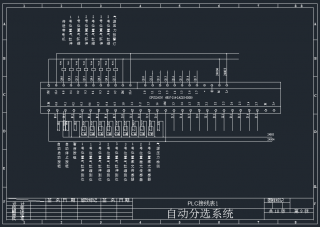

基于PLC的快递分拣系统

2022-11-23 999+

2022-11-23 999+ -

基于PLC的自动送料装车控制设计

2022-11-25 103

2022-11-25 103 -

基于plc的B2012A 型龙门刨床控制电路设计(机械毕业设计+说明书+CAD)

2022-12-07 83

2022-12-07 83 -

基于plc的全自动植树机设计(机械毕业设计+说明书+全套CAD)VIP专免

2022-12-08 435

2022-12-08 435 -

基于PLC的银行排队叫号系统设计(机械毕业设计+说明书+CAD)

2022-12-21 415

2022-12-21 415 -

金属粉末成型液压机PLC设计(机械毕业设计+说明书+全套CAD)

2023-02-06 253

2023-02-06 253 -

基于PLC的物料分拣控制系统(机械毕业设计+说明书+CAD)

2023-02-06 248

2023-02-06 248 -

PLC技术的物料分拣控制系统设计-PLC控制系统设计-机械毕业设计资料自动化设计

2023-10-31 41

2023-10-31 41

相关内容

-

基于三菱PLC对蔬菜称重清洗流水线系统设计-原创PLC控制系统设计-三菱 编程设计

分类:非标机械电气自动化

时间:2024-01-21

标签:设计

格式:ZIP

价格:180 光币

-

基于PLC+组态王的某工厂水箱液位控制系统设计与开发-机械原创毕业设计-PLC控制系统设计

分类:非标机械电气自动化

时间:2024-01-25

标签:设计

格式:ZIP

价格:200 光币

-

建筑垃圾回收利用膏体PLC控制系统设计-机械自动化PLC毕业设计资料-PLC电控系统设计

分类:非标机械电气自动化

时间:2024-01-29

标签:设计

格式:ZIP

价格:200 光币

-

基于西门子PLC恒压供水控制系统设计-PLC控制原创设计资料

分类:非标机械电气自动化

时间:2024-01-29

标签:设计

格式:ZIP

价格:150 光币

-

可调开闭比橡胶鼓包装置电控系统设计-机械毕业设计设计资料-PLC自动控制系统设计

分类:非标机械电气自动化

时间:2024-02-13

标签:设计

格式:ZIP

价格:200 光币